Electrostatic separation

Excessive production of plastic waste is one of the global problems, the solution of which is one of the biggest challenges today. One of the key technologies is the separation of waste into high-purity subcomponents, which can then be recycled. Our project is focused on the technology of electrostatic separation of plastics. The experimental electrostatic precipitator enables the sorting of various types of plastics based on an electric charge generated by friction. At present, the technology aims to replace conventional disposal by landfilling or incineration and thus reduce the impact of industry on the environment.

The electrostatic separator works based on deflecting the plastic crumb in the electrostatic field. Deflection of the pulp can only occur if the pulp is sufficiently charged.

Charging by the triboelectric effect occurs when plastics rub against each other or a conveyor tube. Each of the plastics is charged with a different charge, whether it is of different polarity or intensity. The plastic waste charged in this way is freely dropped into a chamber, which is equipped with two electrodes, between which there is a strong electrostatic field. Due to the repulsion of the opposite polarities of the charges, the waste deflects during the free fall. It is this deflection that is used for separation, thanks to suitably set collectors and collection baskets.

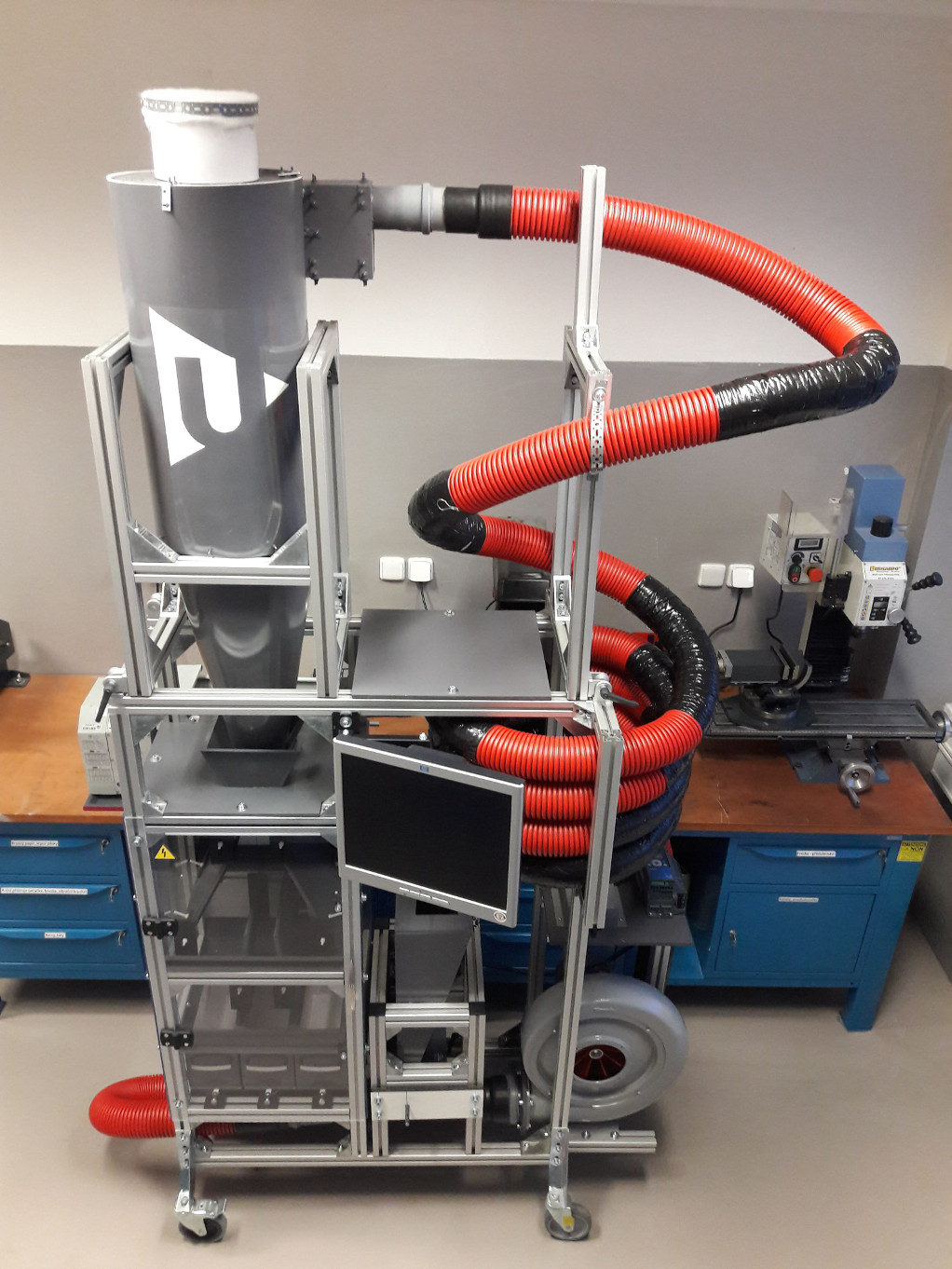

The separator introduced by us could be included in the group of "free-fall" separators. The separator uses hanging electrodes and a plastic material is poured between them in a free fall. A very important part of the whole process is the charging of plastic particles. With the prototype solved by us, charging takes place during the air transport to the separator itself, ie in a plastic tube, which is length-adjusted for optimal charging. The plastic tube is led to a cyclone, where there is an important separation of air from particles. Subsequently, it is necessary to slow down the particles with a rectifier and direct them into the electrode chamber. The proposed technical solution of the separator does not contain any moving parts, therefore it is structurally very simple and also energy-efficient for the operation itself.

Future challenges

- Commercial use of the separator.

- Separation of plastic waste from various metals.

- Sorting of various minerals that must first be purified before they can be further processed.

Publications

Mach, F., Adam, L., Kacerovský, J., Karban, P., & Doležel, I. (2014). Evolutionary algorithm-based multi-criteria optimization of triboelectrostatic separator. Journal of Computational and Applied Mathematics, 270, 134-142.

F. Mach, I. Doležel, V. Kotlan and L. Šroubová, "N-body simulation of electrically charged plastic particles motion in free-fall electrostatic separator," 2017 18th International Symposium on Electromagnetic Fields in Mechatronics, Electrical and Electronic Engineering (ISEF) Book of Abstracts, Lodz, 2017, pp. 1-2, doi: 10.1109/ISEF.2017.8090705.

D. Pánek, P. Karban, F. Mach and D. Ivo, "Utilization of advanced optimization and penalization techniques for calibration of numerical models," 2016 IEEE Conference on Electromagnetic Field Computation (CEFC), Miami, FL, 2016, pp. 1-1, doi: 10.1109/CEFC.2016.7816246.

J. Kacerovský, J. Brabec, F. Mach and P. Karban, "Experimental electrostatic separator for charged particles of plastic mixture," 2016 ELEKTRO, Strbske Pleso, 2016, pp. 523-526, doi: 10.1109/ELEKTRO.2016.7512131.

J. Kacerovský, F. Mach, D. Nikolayev, P. Karban and I. Doležel, "Estimation of charges and critical velocity of plastic particles in triboelectric separator," 2014 ELEKTRO, Rajecke Teplice, 2014, pp. 575-579, doi: 10.1109/ELEKTRO.2014.6848963.

F. Mach, P. Kůs, P. Karban and I. Doležel, "Optimized arrangement of device for electrostatic separation of plastic particles," 2012 ELEKTRO, Rajeck Teplice, 2012, pp. 431-434, doi: 10.1109/ELEKTRO.2012.6225659.